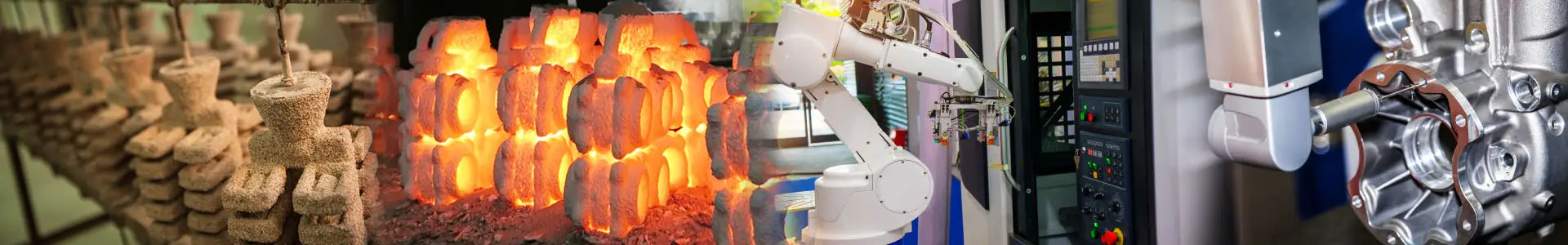

Investment casting

Investment casting is a process of metal forming, which originated in spring and autumn period.It is the wax mold of the parts to be made with special wax. The mold is made of refractory material coated on the surface of the wax mold, and then the wax mold is melted and discharged into the mold shell, and then the molten metal is poured into the mold shell.Casting required after cooling.With high dimensional accuracy and surface finish, some castings can be used directly, which can effectively reduce the machining process.

After more than ten years of experience,Jingcheng company has formed a perfect technical system, with rich casting process experience, can cast nearly 100 different alloy material products.We have comprehensive design and production capacity, including mold design and production, investment casting, heat treatment, precision processing, surface treatment and so on, which can meet the needs of customers in many industries.

| ASTM | JIS | DIN | C | Si | Mn | P | S | Cr | Ni | No | Cu | V | |

| % | % | % | % | % | % | % | % | % | % | ||||

| Stainless steel | CF8 | SCS13 | 1.4308 | 0.07 | 1.5 | 1.5 | 0.04 | 0.03 | 18.0-20.0 | 8.0-11.0 | ≤0.50 | ||

| CF8M | SCS14 | 1.4408 | 0.07 | 1.5 | 1.5 | 0.04 | 0.03 | 18.0-20.0 | 9.0-12.0 | 2.0-2.5 | ≤0.50 | ||

| 304 | SUS304 | 1.4301 | 0.07 | 1 | 2 | 0.045 | 0.015 | 17.5-19.5 | 8-10.5 | N≤0.1 | |||

| 304l | SCS19 | 1.4306 | 0.03 | 1 | 2 | 0.045 | 0.015 | 18.0-20.0 | 10.0-12.0 | N≤0.1 | |||

| 316 | SUS316 | 1.4401 | 0.07 | 1 | 2 | 0.045 | 0.015 | 16.5-18.5 | 10.0-13.0 | 2.0-2.5 | N≤0.1 | ||

| 316L | SCS16 | 1.4404 | 0.03 | 1 | 2 | 0.045 | 0.015 | 16.5-18.5 | 10.0-13.0 | 2.0-2.5 | N≤0.1 | ||

| Carbon steel | WCC | 1.0619 | 0.18-0.23 | 0.6 | 0.50-1.20 | 0.03 | 0.02 | 0.3 | 0.4 | 0.12 | 0.3 | 0.03 | |

| WCB | 0.25 | 0.6 | 1 | 0.04 | 0.04 | 0.5 | 0.5 | 0.2 | 0.3 | 0.03 | |||

| LCC | 1.622 | 0.17-0.22 | 0.6 | 1.1-1.28 | 0.02 | 0.015 | 0.3 | 0.5 | 0.12 | 0.3 | 0.03 | ||

| WC6 | 1.7357 | 0.15-0.2 | 0.6 | 0.5-0.8 | 0.02 | 0.02 | 1-1.5 | 0.4 | 0.45-0.65 | 0.3 | 0.05 | ||

| C45 | 1.0503 | 0.42-0.50 | 0.4 | 0.50-0.80 | 0.045 | 0.045 | ≤0.40 | ≤0.40 | ≤0.10 | ||||

| C45E | 1.1191 | 0.42-0.50 | 0.4 | 0.50-0.80 | 0.03 | 0.035 | ≤0.40 | ≤0.40 | ≤0.10 | ||||

| Low carbon alloy steel | G56NiCrMoV7 | 1.2717 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.03 | 0.03 | 1.00-1.20 | 1.50-1.80 | 0.45-0.55 | 0.07-0.12 | ||

| 31CrMoV9 | 1.8519 | 0.27-0.34 | 0.4 | 0.40-0.70 | 0.025 | 0.035 | 2.30-2.70 | 0.15-0.25 | 0.10-0.20 | ||||

| GX35CrMo17 | 1.4122 | 0.33-0.45 | 1 | 1 | 0.045 | 0.03 | 15.5-17.5 | ≤1.0 | 0.9-1.3 | ||||

| 42CrMo4 | 1.7231 | 0.38-0.45 | 0.6 | 0.6-1.00 | 0.025 | 0.02 | 0.8-1.2 | 0.4 | 0.15-0.3 | 0.3 | 0.05 | ||

| 16MnCr5 | 1.7131 | 0.14-0.19 | 0.4 | 1-1.3 | 0.035 | 0.035 | 0.8-1.1 |

| Casting technology | Max casting weight | Max casting dimension | Min casting thickness | Surface roughness of casting |

| lost-wax process | 60kg | 600mm×600mm×600mm | 2mm | Ra3.2μm |

-

MPT

-

MPT

X-ray testing

MPT

X-ray testing

-

X-ray testing

Spectrum analysis

X-ray testing

Spectrum analysis

-

Spectrum analysis

Automatic shell making

Spectrum analysis

Automatic shell making

-

Automatic shell making

Wax pattern

Automatic shell making

Wax pattern

-

Wax pattern

Wax pattern

Wax pattern

Wax pattern

-

Wax pattern

Wax pattern