Precision machining

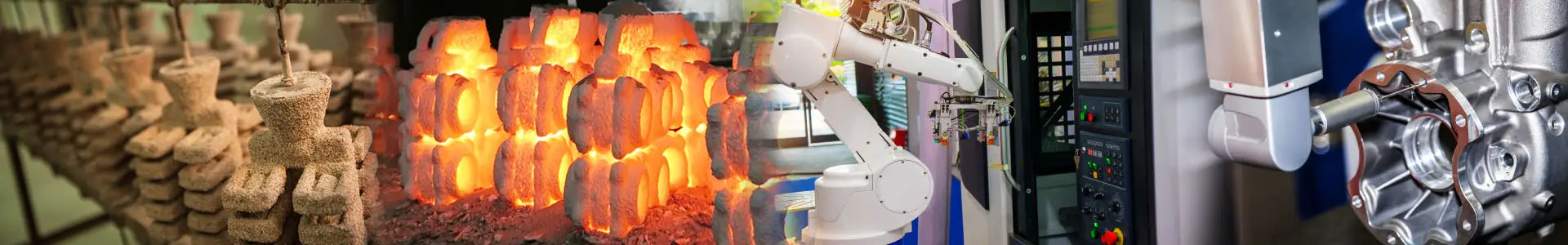

Jingcheng adopts advanced numerical control lathe and machining center to form high-precision metal parts through milling, cutting, drilling and tapping.

Precision machining dimension is less tolerance of precision than casting size. First of all, we will control the size of the casting products within the tolerance range required by customers through the calibration method. As there is no need for precision processing, the production time is relatively short. If precision machining is required to obtain the required size, our engineers will choose the best processing technology at the design stage and choose the most suitable processing equipment to reduce the processing cost.

Through more than 10 years of technical accumulation, Jingcheng can batch and stable production of high-precision and high-complexity parts from 0.5 mm up to 200 mm.

| Brand | Type | Quantity(station) | Equipment | Max machining dimension | Max machining accuracy |

| LGMAZAK | VCS530CL | 1 | 5-axis MC | 1050*350*510mm | 0.01mm |

| LGMAZAK | VTC-20B | 1 | 4-axis MC | 1120*510*510mm | 0.01mm |

| LGMAZAK | VTC-160AN | 2 | 4-axis MC | 560*410*510mm | 0.01mm |

| LGMAZAK | QT-200 | 11 | CNC | 300*300mm | 0.01mm |

| TAKISAWA | NEX-108 | 4 | CNC | 300*200mm | 0.01mm |

| HYUNDAI WIA | F500 | 1 | 5-axis MC | 1200*500*785mm | 0.01mm |

| HYUNDAI WIA | SKT15Z | 3 | CNC | 300*200mm | 0.01mm |

| HYUNDAI WIA | E200MC | 1 | Milling center | 300*300mm | 0.01mm |

| Kaibo | DC-8070A | 2 | CNC | 800*700*300mm | 0.01mm |

| Domestic brand | VMC850B | 2 | 4-axis MC | 800*500*550mm | 0.01mm |

| Domestic brand | CL-15 | 6 | CNC | 300*200mm | 0.01mm |

| Hexagon Metrology | EXPLORER08.10.06 | 1 | CMM | 800*1000*600mm | (2.5+3.3L/1000)μm |

| Hexagon Metrology | EXPLORER05.07.05 | 1 | CMM | 500*700*500mm | (2.7+3.5L/1000)μm |